INNOVATIVE NEW INJECTION-MOULDED HANDLEBAR MANUFACTURING TECHNIQUE PIONEERED BY CANYON BICYCLES AND ENGEL

New technique promises design freedom, time saving and performance benefits associated with high-end carbon, plus near-shoring benefits through European production.

Embargoed until 11:00 CEST, Tuesday 24th June, 2025: Innovation in manufacturing technologies rarely gets the limelight it deserves - it's the final product that usually causes excitement - but now, thanks to a new injection-moulding manufacturing technique developed by Canyon Bicycles and Engel, it's time to literally shine a light on (or from) this new technique.

Canyon's thermo-plastic, reinforced carbon-fibre cockpit not only sets a new benchmark in terms of production speed, cost, and design, but it also incorporates semi-integrated cabling and a headlight in the cockpit.

This new CP0051 Canyon cockpit is designed for use on Canyon’s Roadlite 2026 range, where it promises the sleek design, high quality finish and compliance strength usually associated with high-end carbon manufacturing techniques, but instead comes from a more affordable and quicker-to-manufacture thermo-plastic, injection-moulding technique.

Developed together with Engel and their injection moulding solutions, the technology allows for advanced features such as semi-cable integration, light integration and integrated smart phone mounts to be included in a manufacturing process that takes a fraction of the time it would take to make these parts out of carbon fibre.

What would previously take two days in a batch process can now be made by Engel’s machinery in a matter of one minute as part of a mass production process that also guarantees consistent parts quality.

This innovation in production provides Canyon with the design freedom to employ this technology and production methodology on a range of other high-end Canyon Engineered Parts in future, reducing the cost of components and potentially allowing for increased value elsewhere on its bikes.

As well as speeding up production times, the other added benefit comes from being able to near-shore the production within Europe, reducing freight costs and CO2 transportation emissions.

The use of carbon in the manufacture of bicycle frames is not a mass production process. A lot of hand work is involved. We’ve been able to build handlebars that have similar compliance and strength properties to carbon fibre bars, but in a mass production process that takes a fraction of the time and ensures perfect quality. This is a big step in manufacturing terms and the innovation will bring benefits for consumers in terms of value when this is used as part of a complete bicycle.Wolfgang Kohl, team manager of Canyon's Innovation Lab

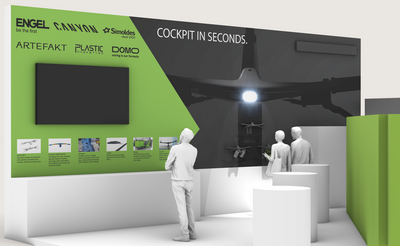

Customers interested to see this manufacturing technique up close can visit the Engel booth (Hall 8, Stand N 04) at Eurobike, which takes place from 25 to 29 June in Frankfurt, where Canyon handlebars will be made on-site.

For fans eager to get their hands on these bars though, they’ll have to wait until the bars come as part of a complete bike, due for launch in summer 2026.

For more on this story, see Engel's website here.